Discover Hammer Mills

Our hammer mills are designed for high efficiency and low power consumption. Experience the power of advanced mineral processing with our state-of-the-art equipment.

Understanding the Hammer Mill's Operational Process

The hammer mill primarily crushes material through impact. Material enters the mill and is rapidly struck by a high-speed rotary hammer, gaining kinetic energy. It then collides with internal baffles and sieve strips, smashing against itself to achieve the desired granularity.

- High Efficiency: Achieves fine crushing and coarse grinding.

- Durable Materials: Made with high manganese alloy for wear resistance.

- Simple Structure: Easy installation and maintenance.

Explore Diverse Applications of Hammer Mills

Suitable for mining, cement, coal, metallurgy, building materials, highway, burning and other industries to medium hardness andbritle materials for fine crushing. Can break al kinds of hard and abrasive materials. and the compressive strength of its material is notmore than 100 MPa, and the moisture content is less than 15%.

Mining Industry Applications

Hammer mills are crucial in mining for crushing ores and minerals, ensuring efficient processing and extraction.

Cement Industry Uses

In the cement industry, hammer mills help in grinding raw materials, contributing to the production of high-quality cement.

Construction Sector Benefits

Hammer mills aid in recycling and processing construction materials, promoting sustainable building practices.

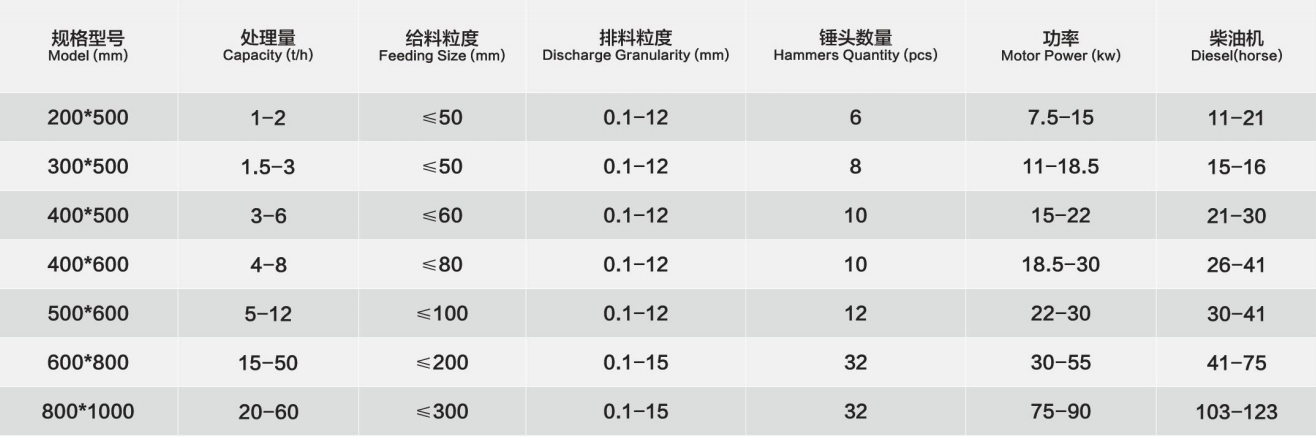

Technical Specifications

Discover the detailed specifications of our mineral processing equipment and gold extraction reagents. Navigate through the tabs to explore the features and technical details of each product category.