Discover the of Crushing

MEW Solutions presents the Double Roller Crusher, engineered for high efficiency and durability. Experience unparalleled crushing power with our state-of-the-art equipment.

Explore Our Advanced Equipment Features

Double Roller crushers use two durable, wear-resistant alloy rollers to crush material through high squeezing force from their rotation. As material enters the V-shaped gap, it is crushed by the combined forces of squeezing and shearing. The finished product is then discharged from the machine’s lower port. The double roller crusher has two types of roller surfaces—flat and surfacing—allowing customization based on user needs. For materials with compressive strength over 200 MPa, heavier models are available.

Roller Crusher Usage Range

The roller crusher is ideal for medium and fine crushing operations of materials with compressive strength under 300Mpa and moisture below 35%. It is extensively used in industries such as mining, thermoelectricity, cement ceramics, metallurgy, and building materials.

- Mining

- Thermoelectricity

- Cement Ceramics

- Metallurgy

- Building Materials

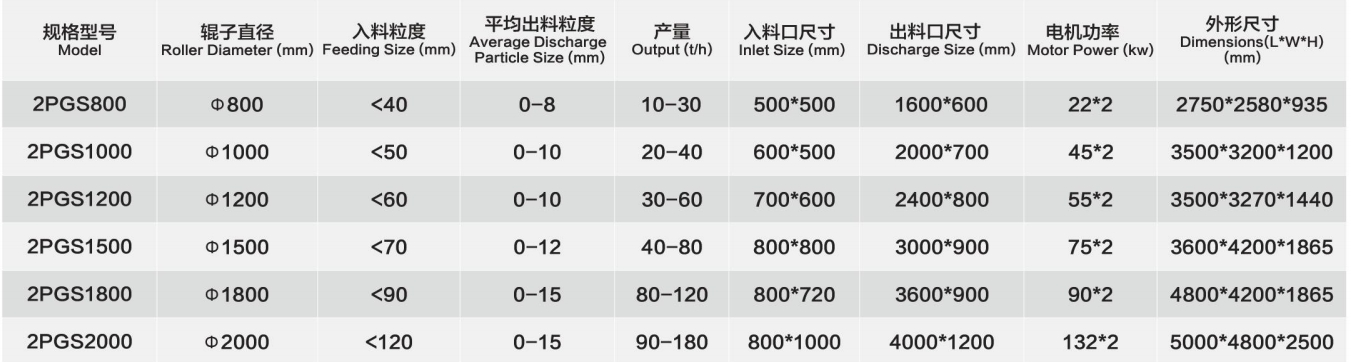

Double Roller Crusher Specs

Explore the technical specifications of our Double Roller Crusher. Designed for high efficiency and durability, it features two high-strength alloy rollers. Ideal for medium and fine crushing operations, it handles materials with compressive strength up to 300Mpa.